Hyperspectral imaging is an advanced imaging technique that incorporates spectroscopy to gather additional information about an object or geographical area. It involves capturing many images of the same spatial area over a series of contiguous spectral bands across the UV, visible, and/or NIR, yielding an additional dimension of information for each pixel of an object or scene.

Hyperspectral imaging is an advanced imaging technique that incorporates spectroscopy to gather additional information about an object or geographical area. It involves capturing many images of the same spatial area over a series of contiguous spectral bands across the UV, visible, and/or NIR, yielding an additional dimension of information for each pixel of an object or scene.

Conventional imaging cameras gather ‘RGB’ image data from three primary wavebands across the visible portion of the electromagnetic spectrum (red, green, and blue). To improve image fidelity, they typically filter out or compensate for extraneous signals that are beyond the range of the naked eye, mimicking only what the human eye can see. Obtaining the unique spectral fingerprints of materials can yield highly valuable information, but requires the ability to capture data across the ultraviolet (UV), visible, near infrared (NIR), and/or short-wave infrared (SWIR) regions.

Hyperspectral imaging takes this concept further, simultaneously acquiring imaging and spectroscopic data to determine the unique spectral fingerprint of each pixel in the imaged scene. This is extremely useful in material, object, or process identification.

How Hyperspectral Imaging Works

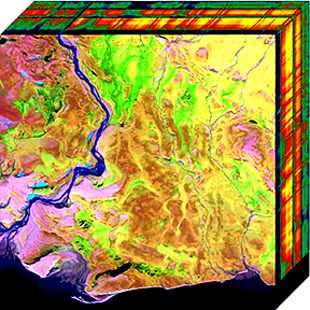

Hyperspectral imaging cameras scan an object or scene using numerous spectral channels to produce a series of ‘hyperspectral’ images. They collect a sequence of wavelengths relevant to the desired application with resolutions ranging from one to several nanometers (nm). The image set is then combined into a 3D hyperspectral data cube featuring two spatial dimensions and a third spectral dimension comprising a range of wavelengths. Obtaining the full spectrum of interest requires several spectral channels with marginal steps between each one. Multispectral imaging, in contrast, may select for only a few specific wavebands of interest to an application, which may not be contiguous.

Uses of Hyperspectral Imaging

The slow acquisition rates and relatively high instrument cost of hyperspectral imaging have prohibited some users from deploying hyperspectral cameras in key areas. However, significant developments in remote sensing, sensor technologies in general, and smaller format—yet more robust—optical components, have made it a more attractive solution for an array of application areas, including:

- Agriculture

- Environmental monitoring

- Process industries

- Research

- Surgery

Gratings for Hyperspectral Imaging

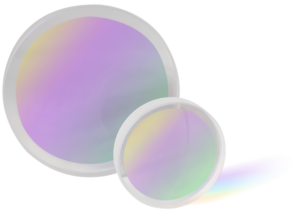

At Wasatch Photonics, we design and manufacture VPH gratings for hyperspectral imaging which offer much greater efficiency than conventional ruled gratings. Our patented broad bandwidth grating designs offer low polarization sensitivity and uniform spectral efficiency with less stray light, plus low transmitted wavefront error for clearer images. The robust, encapsulated nature of transmissive VPH gratings enables easier handling, cleaning, and alignment in optical systems than ruled reflective gratings, making them a clear choice for industrial hyperspectral imaging systems. Transmissive VPH gratings also allow smaller form factor spectrographs, particularly if configured as a grism to enable a straight-pass optical design.

At Wasatch Photonics, we design and manufacture VPH gratings for hyperspectral imaging which offer much greater efficiency than conventional ruled gratings. Our patented broad bandwidth grating designs offer low polarization sensitivity and uniform spectral efficiency with less stray light, plus low transmitted wavefront error for clearer images. The robust, encapsulated nature of transmissive VPH gratings enables easier handling, cleaning, and alignment in optical systems than ruled reflective gratings, making them a clear choice for industrial hyperspectral imaging systems. Transmissive VPH gratings also allow smaller form factor spectrographs, particularly if configured as a grism to enable a straight-pass optical design.

Read More: 5 Applications of Transmission Gratings

Designing a new hyperspectral imaging system for an agricultural, medical, or industrial application? Let our expert staff consult with you to design a custom grating or optical bench to meet your application needs.

Designing a new hyperspectral imaging system for an agricultural, medical, or industrial application? Let our expert staff consult with you to design a custom grating or optical bench to meet your application needs.