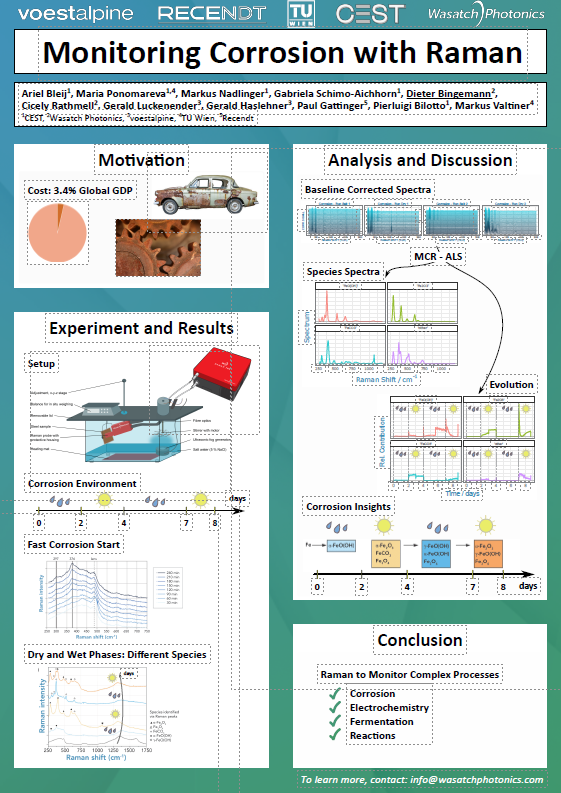

Wasatch Photonics partnered with CEST and Vienna University of Technology in Austria to support a novel in situ study of corrosion processes using Raman spectroscopy. The study monitored corrosion products on metal surfaces using a compact, probe-based Raman spectrometer in a salt fog chamber.

The process of corrosion is complex and difficult to manage. The established, commonly used experimental techniques provide only limited information. A standardized test, the neutral salt spray test, used to evaluate the corrosion resistance of steels and coatings previously is not suitable for many analytical methods. This in situ study of corrosion using Raman spectroscopy to detect the formation, growth, and evolution of corrosion products on metal surfaces was conducted by monitoring a mild steel plate in alternating salt fog and dry atmospheric conditions over a period of eight days to identify and track key corrosion products.

It is estimated that corrosion costs about 3.4% of the annual global gross domestic product. Research institutions and industries from steel and automotive to oil and gas use different techniques to understand, predict and control corrosion-related processes, including the development or use of coatings and alloys to extend the life span of steel products. The key to improving the cost of corrosion both directly and indirectly in terms of safety and environmental costs, is to better understand the corrosion mechanisms.

In this study, which included Wasatch Photonics’ Senior Staff Scientist Dieter Bingemann, PhD., and used our WP 785 Raman spectrometer, a test was conducted in situ using Raman spectra inside a working salt fog chamber demonstrating the possibility for online investigation of the corrosion process in low carbon steel. Successful use of a compact, cost-effective spectrometer system is an important advance in the field of corrosion monitoring, as it puts in situ monitoring within reach for a much wider range of research and industrial labs. The Wasatch Photonics Raman system employed was sensitive enough to clearly identify five unique iron species present during the corrosion process and track their evolution through the various stages of the salt fog test, making it a viable tool for in situ studies of corrosion across a wide range of needs – in the lab or in the field.

Investigating new areas where Raman spectroscopy can be applied to better understand and solve problems that bridge the lab and the field is a key part of our mission at Wasatch Photonics. We wish to extend our thanks to CEST and the Vienna University of Technology for collaborating with us on this study.

Read the full article in Spectroscopy Magazine’s June Raman supplement, or see our poster below:

Learn more about the products used in this study:

June 15, 2022