A DIY optical coherence tomography setup or system can be fun to build, but requires multiple optical and mechanical components, an understanding of signal and image processing, some programming expertise, and a significant investment of time. Using a prebuilt, off-the-shelf SD-OCT spectrometer as one of the starting components can speed and simplify this process, reduce risk, and improve the quality of images collected. In this tech note, we’ll introduce you to some of the key principles and layout of a DIY optical coherence tomography setup and share our expert tips on how to get the best performance from the OCT spectrometer portion of your design – whether you plan to build the spectrometer yourself or buy one.

Download this tech note

OCT Principles

Optical coherence tomography is an optical version of ultrasound, replacing the sound waves with light. Although OCT can’t probe as deeply (typically millimeters), it delivers images with much higher resolution than ultrasound, without the need for direct contact or use of a coupling medium. It provides surface profiles and information about subsurface structure and uniformity that can be useful in medical applications like ophthalmology, cardiology, and research, as well as in industrial inspection.

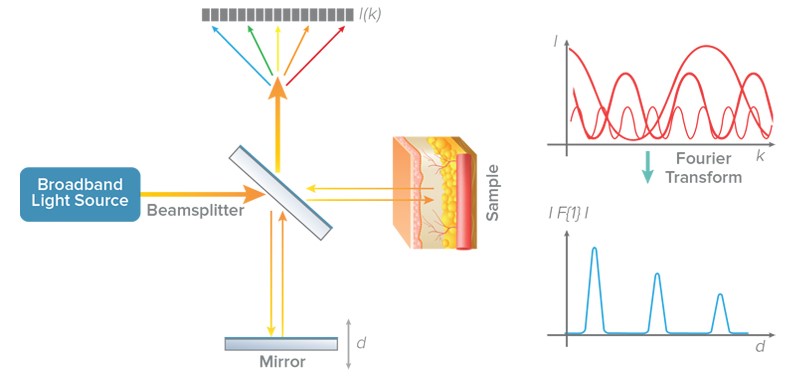

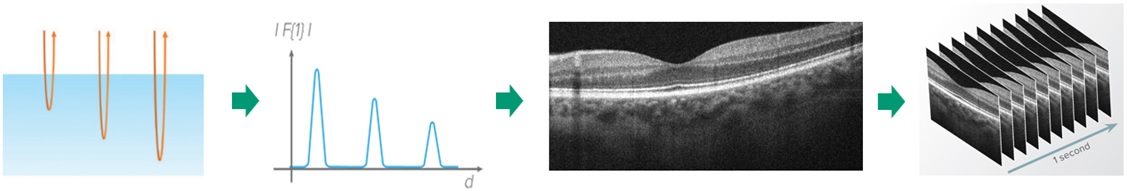

OCT uses low-coherence interferometry with visible or infrared light in combination with scanning across the sample to generate a series of cross-sectional images or 3D volume. There are several ways low-coherence interferometry can be performed, but two of the most popular ways are swept-source (SS-OCT) and spectral-domain (SD-OCT). Both methods shine laser light of multiple wavelengths on the sample and then measure the different wavelengths of scattered light that are returned, taking a Fourier transform of the spectrum to detect structures at different depths.

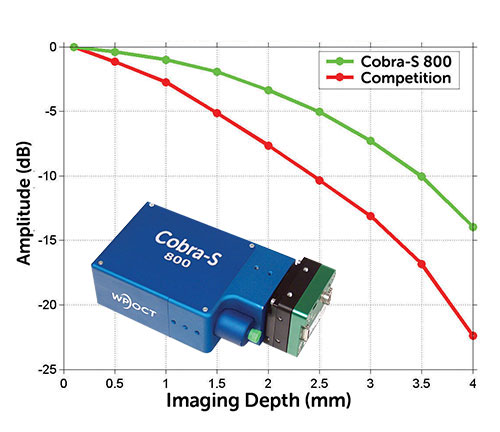

In swept-source OCT (SS-OCT), the laser is scanned in wavelength, and a single-element photodetector captures the signal. In spectral-domain OCT (SD-OCT), a broadband laser source is used in combination with a multi-element detector like a spectrometer. SS-OCT offers high speed and low roll-off (we’ll explain that term later) but is expensive due to the high cost of swept-source lasers. SD-OCT yields better resolution at lower cost, but it wasn’t able to compete on speed and roll-off performance – until better imaging cameras were introduced, several years ago. At Wasatch Photonics, we were the first to integrate these new cameras into our Cobra-S OCT spectrometer product line to offer industry-leading SD-OCT, starting in 2017.

Left: OCT conceptual schematic showing how low-coherence interferometry can be used to determine structure within a 3-dimensional material. Right: A comparison of key performance parameters for SS-OCT, traditional SD-OCT, and high-speed OCT using Cobra-S OCT spectrometers from Wasatch Photonics.Building a DIY optical coherence tomography setup or system

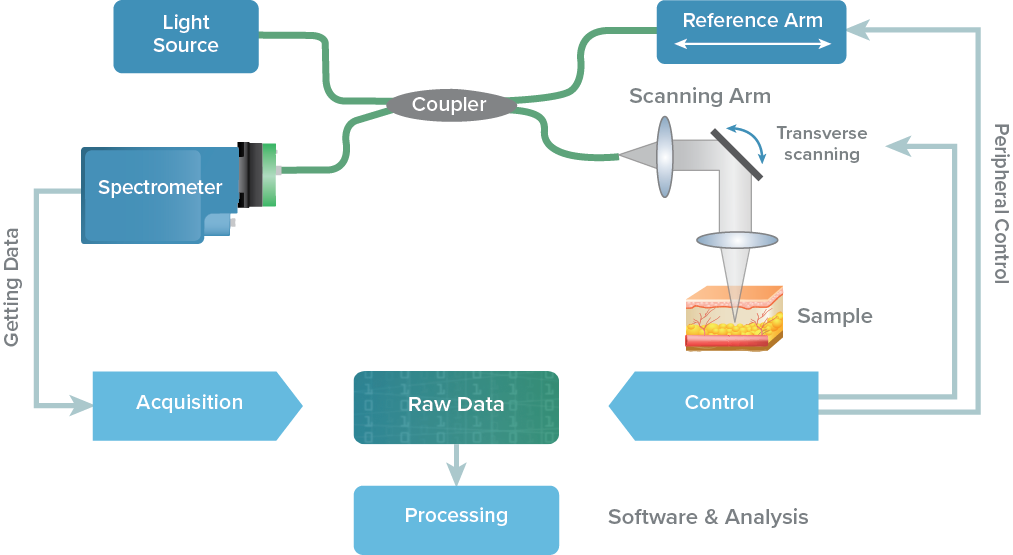

In an SD-OCT system, broadband laser light is split between two paths: one to a reference arm and one to the sample to be measured. Light returning from these two paths is recombined and interferes to generate a fringe pattern which is read by the spectrometer, which digitizes the intensity at each wavelength. Either a supercontinuum laser or lower cost superluminescent diode (SLED) can be used as the light source. To generate a cross sectional OCT image, the laser beam must be scanned quickly across the sample with a high-speed scanning mechanism such as a galvanometer or MEMS-based device.

Software must be written to communicate with both the spectrometer and scanning arm to synchronize data collection with the beam scanning, and to process the spectra collected by converting the frequency data to time data using fast Fourier transforms.

The key modules of the DIY SD-OCT system like SLEDs, optical couplers, and reference arms are produced with advanced manufacturing techniques and can be purchased off-the-shelf. The OCT spectrometer is a unique module that utilizes cameras and sensors produced via semiconductor manufacturing methods, along with custom optical elements in precise alignment. This makes the OCT spectrometer a particularly challenging part of the DIY OCT system, and worthy of discussion in more detail.

What makes a good OCT spectrometer?

The OCT spectrometer used in a DIY optical coherence tomography setup has a huge impact on the quality of images collected – influencing the imaging depth, resolution, speed of image acquisition, and contrast in the image. Low ‘roll-off’ (or loss of sensitivity with depth) is the key performance parameter for any OCT spectrometer and is determined by the spectrometer design.

Here are some qualities to look for when purchasing or designing an OCT spectrometer:

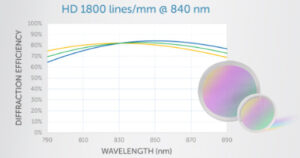

High efficiency at all wavelengths: The reflected light in OCT is very low intensity, therefore a highly sensitive spectrometer will substantially improve image quality. And since OCT uses a Fourier transform of the spectrum, every wavelength in that spectrum is important. The more uniform the spectrometer response is with wavelength, the better the image quality. Use of a high efficiency, broadband grating in the spectrometer is very important, and Wasatch Photonics offers the best. Explore our industry-leading OCT gratings

High efficiency at all wavelengths: The reflected light in OCT is very low intensity, therefore a highly sensitive spectrometer will substantially improve image quality. And since OCT uses a Fourier transform of the spectrum, every wavelength in that spectrum is important. The more uniform the spectrometer response is with wavelength, the better the image quality. Use of a high efficiency, broadband grating in the spectrometer is very important, and Wasatch Photonics offers the best. Explore our industry-leading OCT gratings- Insensitivity to polarization: Given that OCT is an interferometric technique, often using fiber optics for transmission, this makes the system highly sensitive to polarization changes. While most components in a spectrometer are polarization-insensitive, several grating families used in spectrometers can have strong polarization dependence, and hence are not suitable for OCT imaging. VPH transmission gratings have very low polarization sensitivity, which is why Wasatch Photonics is the leading supplier of OCT gratings worldwide. Learn more about the advantages of VPH gratings

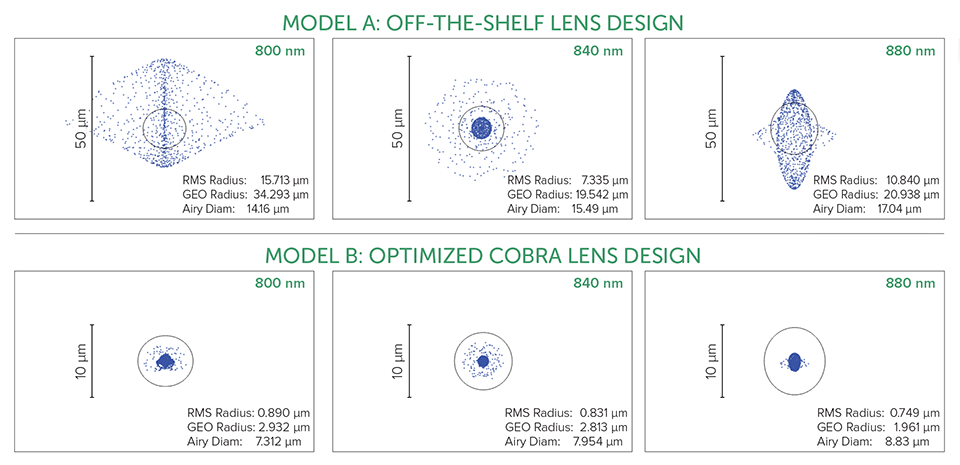

- Diffraction-limited optical design: Off-the-shelf optics often fail to deliver high clarity OCT images because the optical constraints to obtain good roll-off are so stringent. The spot size of light imaged on each camera pixel must be small to avoid spread to neighboring pixels, and this must be true for the wide range of wavelengths used in the spectrometer. At Wasatch Photonics, we design and source custom lens sets that match our spectrometer designs perfectly, yielding optimized spectrometer performance for OCT at all wavelengths that far outperforms use of off-the-shelf lenses. To learn more about this, read our tech note, Optimizing OCT Spectrometer Performance.

- A high speed, high fidelity camera: While careful optical design can significantly reduce roll-off in an OCT spectrometer, crosstalk between camera pixels can limit the performance that can be achieved. At Wasatch Photonics, we use high sensitivity, low crosstalk cameras such as the e2v OctoPlus camera used in our Cobra-S spectrometers. It offers scan rates up to 250 kHz, which is comparable to most commercial SS-OCT speeds.

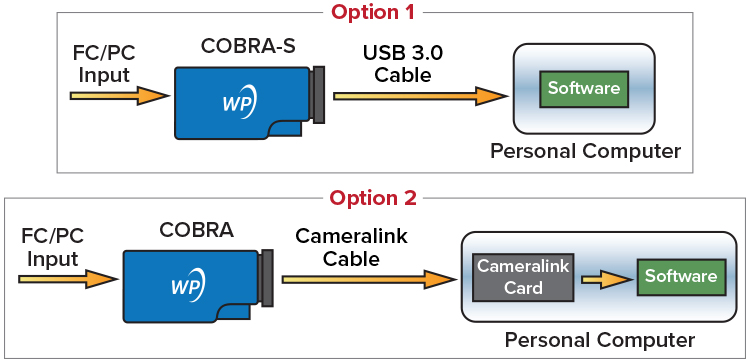

- Choice of camera connection: Data transfer from the camera used to collect OCT spectra may be achieved through a camera link card or over USB cable, depending on the camera model. Camera link communication allows for faster scan speeds and a more stable platform, but it requires purchase of a camera link card and a computer in which to install it. USB 3.0 communication, on other hand, allows a laptop to be used for scanning, but only up to 130 kHz; it also requires camera-dependent software development. At Wasatch Photonics, we offer both options to give you the flexibility you need.

- SDKs to simplify camera communication: The cameras used in OCT spectrometers have many other uses, and come with extensive, complex manuals of commands for control and data acquisition that can be time-consuming to sift through. That’s why Wasatch Photonics OCT spectrometers come with software development kits – a set of streamlined, OCT-specific commands and sample GUIs that allow you to begin acquiring images in just 30 minutes from any OCT spectrometer we offer, saving days to weeks of software development time with guaranteed results.

Preconfigured OCT spectrometers for DIY OCT systems

Choosing to purchase a preconfigured OCT spectrometer instead of building your own has many advantages, from improved performance (and thus better images!) to considerable time savings in optical design, build, and software development. This allows you to focus on your application with confidence that you are collecting the best images possible.

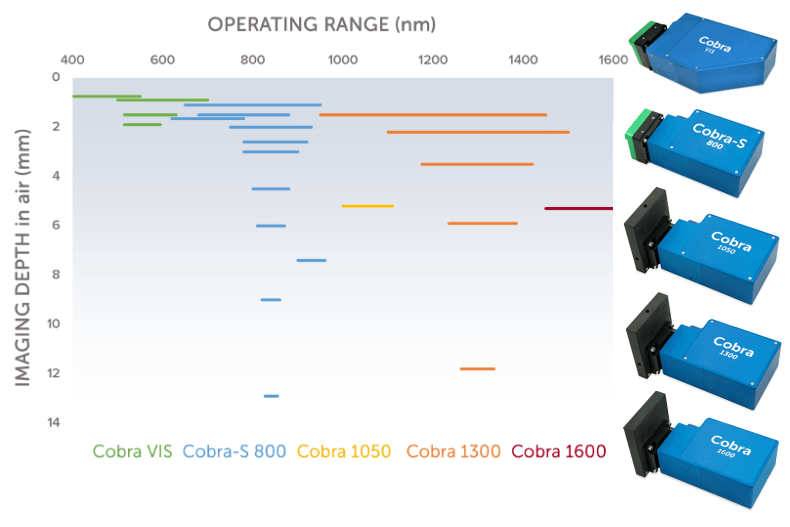

Wasatch Photonics offers an unparalleled breadth and range of OCT spectrometers at wavelengths from the visible through to 1600 nm, with speeds up to 250 kHz, allowing you to find your perfect fit. Choose the center wavelength and bandwidth for the depth and resolution you need, then select the camera, speed, and connection right for your application. Explore our Cobra OCT spectrometer series

Streamlining OCT system design for OEMs

If you are designing an OCT system for commercial use, as a standalone ophthalmology or nondestructive testing instrument, or as complementary imaging for surgical guidance, you may have additional size and integration restrictions.  That’s why we’ve designed a smaller, lighter, and highly robust OCT spectrometer specifically for OEMs. It offers comparable performance to our signature Cobra-S OCT spectrometer, and is offered in multiple models matched to available SLD sources for cost-effective OCT imaging in volume. Wasatch Photonics’ OCT spectrometers meet the stringent requirements for thermal and mechanical performance required in medical devices, and have been designed into devices that are compliant with regulations like IEC 60601. Explore our ‘compact without compromise’ OEM OCT spectrometers.

That’s why we’ve designed a smaller, lighter, and highly robust OCT spectrometer specifically for OEMs. It offers comparable performance to our signature Cobra-S OCT spectrometer, and is offered in multiple models matched to available SLD sources for cost-effective OCT imaging in volume. Wasatch Photonics’ OCT spectrometers meet the stringent requirements for thermal and mechanical performance required in medical devices, and have been designed into devices that are compliant with regulations like IEC 60601. Explore our ‘compact without compromise’ OEM OCT spectrometers.

Whether you have a new application or an existing system, our experienced team will help you find the ideal OCT grating or spectrometer for your research or new product development. Contact us today to discuss your unique needs.