This June, we had the pleasure of sitting as industry judges at a very unusual competition for applied spectroscopy company start-ups. The contestants were all PhD students, and just one week before, some of them had never touched a spectrometer in their lives.

This June, we had the pleasure of sitting as industry judges at a very unusual competition for applied spectroscopy company start-ups. The contestants were all PhD students, and just one week before, some of them had never touched a spectrometer in their lives.

The competition goes under the unassuming name of ‘Build Your Own Spectrometer Course’, and it’s the culmination of a week-long hands-on training session taken by first year PhD students participating in the CDT OPTIMA program at the Universities of Strathclyde and Edinburgh in Scotland. The Engineering and Physical Sciences Research Council (EPSRC) in the UK funds many such Centres for Doctoral Training to encourage interdisciplinary research between institutions and the development of skills transferable to industry.

CDT OPTIMA offers a 4-year PhD program with a focus in Optical Medical Imaging, combining research in world-class scientific groups with a concentrated program of business training in healthcare innovation and entrepreneurship. PhD research projects look at opportunities for clinical innovation, developing cutting-edge optical imaging and sensing techniques to solve fundamental clinical problems.

Build Your Own Spectrometer Course

OPTIMA’s Build Your Own Spectrometer course is a hands-on week that teaches 1st year PhD students the basics of spectroscopy and spectrometer design through a series of lectures, independent study exercises, and workshops. It’s the brainchild of Professor Karen Faulds at the University of Strathclyde and Neil Shand, visiting professor. Both are as active at the forefront of spectroscopy as they are in all aspects of the course, bringing a tremendous wealth of expertise on the bridge between research and industry.

Armed with knowledge of spectroscopy techniques like Raman, NIR, and fluorescence, they are then challenged to design, build, and optimize a system to address a specific application. Each team of 3-4 students is given a breadboard-style platform with interchangeable components which they must then select, place, align, and calibrate to create their system.

At the end of the week, they must pitch their application-specific product to a group of judges from industry and OPTIMA with a presentation and marketing flyer, justifying their design with data and comparing their instrument’s performance with commercial instruments. This holistic approach to product design, development, and marketing challenges the students to move beyond thinking of a spectrometer as a ‘black box’ and exposes them to product development with an industry mindset. As part of the judging team, we at Wasatch Photonics were impressed with the the products they developed, the very practical discoveries they made along their way, and their savvy in marketing the end products.

Meet the 2019 Teams

Cosy Photon – Premium Raman for research

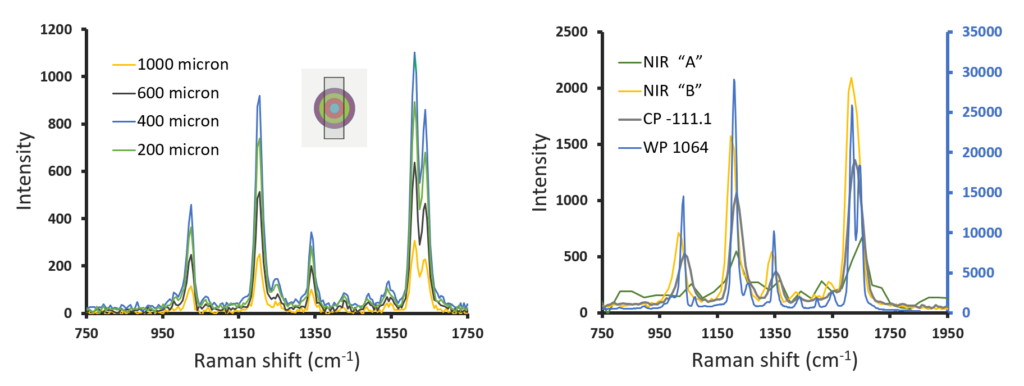

Cosy Photon’s task was to develop a Raman spectrometer capable of detecting nanoparticles on the surface of cancer cells using SERS (surface enhanced Raman spectroscopy). The challenge? It needed to deliver maximum throughput and high performance consistent with needs in medical research. After surveying the literature, the team chose 1064 nm excitation to minimize fluorescence from the cellular matrix, testing different gratings, slits, and optical fibers to maximize the signal from SERS nanoparticles, creating the “CP-111.1”. They discovered that a larger detection fiber doesn’t always mean more signal, and that commercial instruments have many, more subtle, design differences that help to deliver more signal. (We couldn’t help be a little bit proud that our WP 1064 had to be plotted on a secondary axis for comparison purposes!)

Cosy Photon’s task was to develop a Raman spectrometer capable of detecting nanoparticles on the surface of cancer cells using SERS (surface enhanced Raman spectroscopy). The challenge? It needed to deliver maximum throughput and high performance consistent with needs in medical research. After surveying the literature, the team chose 1064 nm excitation to minimize fluorescence from the cellular matrix, testing different gratings, slits, and optical fibers to maximize the signal from SERS nanoparticles, creating the “CP-111.1”. They discovered that a larger detection fiber doesn’t always mean more signal, and that commercial instruments have many, more subtle, design differences that help to deliver more signal. (We couldn’t help be a little bit proud that our WP 1064 had to be plotted on a secondary axis for comparison purposes!)

What was the most useful thing you learned this week?

I found it helpful to understand the relationship between grating and resolution. I always just used the grating setting that the post doc told me to. Now I think I’ll play around with the grating more, as I think resolution is going to be important for my own research project.

– Grant Cumming

SpecDRA – Detection of counterfeit spirits

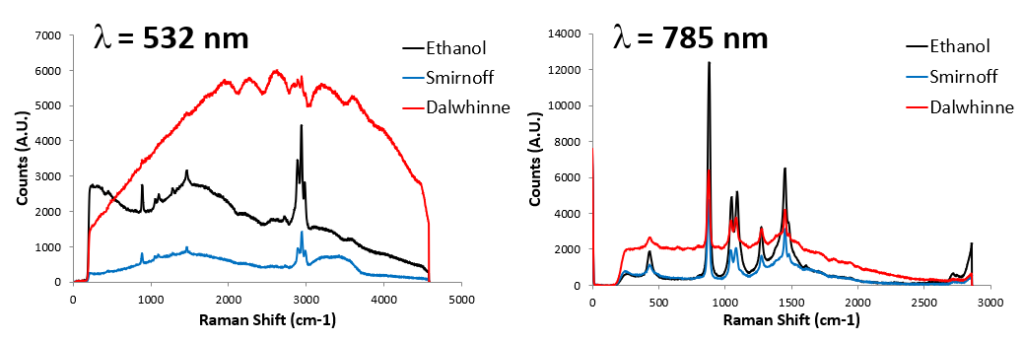

SpecDRA’s task was to build a Raman spectrometer for a manufacturer and distributor of premium spirits that was capable of identifying counterfeit alcohol. The challenge? Make it low cost and potentially portable for on-site, out-of-lab inspection. This forced them to look how they could achieve sufficient signal while keeping cost and weight down. The team explored the use of different excitation wavelengths to minimize autofluorescence when looking at darker spirits and through-bottle, settling on 785 nm. They also compared optical components like grating, slit, and front-illuminated vs back-thinned detectors to balance performance and cost.

SpecDRA’s task was to build a Raman spectrometer for a manufacturer and distributor of premium spirits that was capable of identifying counterfeit alcohol. The challenge? Make it low cost and potentially portable for on-site, out-of-lab inspection. This forced them to look how they could achieve sufficient signal while keeping cost and weight down. The team explored the use of different excitation wavelengths to minimize autofluorescence when looking at darker spirits and through-bottle, settling on 785 nm. They also compared optical components like grating, slit, and front-illuminated vs back-thinned detectors to balance performance and cost.

SpectroProbe – Quality control of fluorescently labeled antibodies

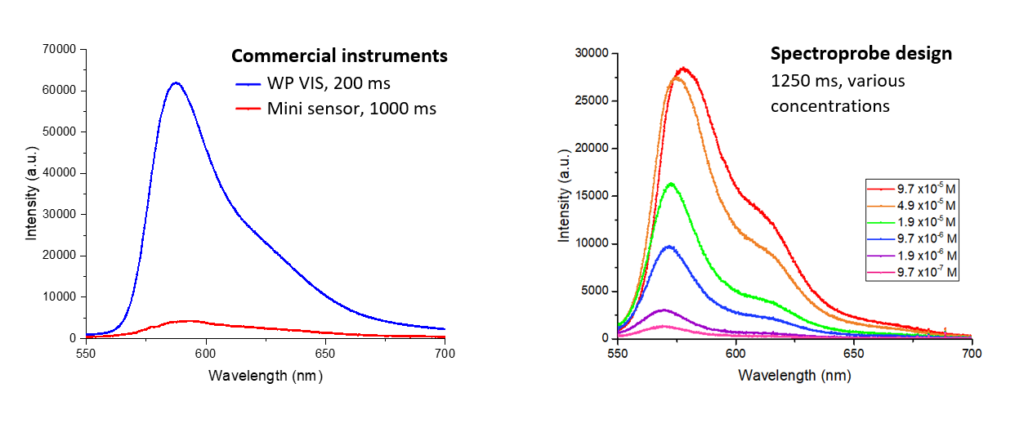

SpectroProbe’s task was to develop a fluorescence-based sensor for a manufacturer who produces fluorescently labeled antibodies for medical imaging applications. The challenge? The instrument needed to be capable of identifying the presence of fluorescently labeled antibodies, and of quantifying the amount produced, yet be low cost and very sensitive. The team began by scoping out the competition, looking at the sensitivity and footprint of various commercially available spectrometers to establish a baseline. They were able to achieve intermediate sensitivity between the two by making optical component choices strategically to keep costs down. The calibrated system was able to see concentrations as low as 9.7 x 10-7 M of Rhodamine B dye.

SpectroProbe’s task was to develop a fluorescence-based sensor for a manufacturer who produces fluorescently labeled antibodies for medical imaging applications. The challenge? The instrument needed to be capable of identifying the presence of fluorescently labeled antibodies, and of quantifying the amount produced, yet be low cost and very sensitive. The team began by scoping out the competition, looking at the sensitivity and footprint of various commercially available spectrometers to establish a baseline. They were able to achieve intermediate sensitivity between the two by making optical component choices strategically to keep costs down. The calibrated system was able to see concentrations as low as 9.7 x 10-7 M of Rhodamine B dye.

R2 Lasers – SERS microscope for research

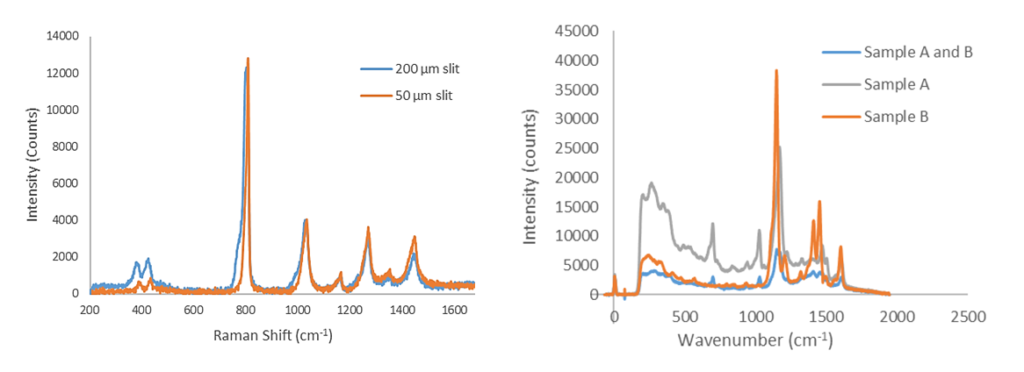

R2 Lasers’ task was to produce a high resolution 785 nm SERS Raman microscope to detect nanoparticles on the surface of cancer cells. The challenge? It needed superior performance with high end specifications to enable use in a range of medical research applications. The team designed their “Hydra 785” instrument to cover the Raman fingerprint region, optimizing signal with a back-thinned detector, and choice of 400 and 600 µm core fibers for mating to the microscope. They found that a larger slit gave them the signal they needed for smaller peaks at a 5 second integration time, and even explored the viability of analyzing mixtures as a test of multiplexed detection.

R2 Lasers’ task was to produce a high resolution 785 nm SERS Raman microscope to detect nanoparticles on the surface of cancer cells. The challenge? It needed superior performance with high end specifications to enable use in a range of medical research applications. The team designed their “Hydra 785” instrument to cover the Raman fingerprint region, optimizing signal with a back-thinned detector, and choice of 400 and 600 µm core fibers for mating to the microscope. They found that a larger slit gave them the signal they needed for smaller peaks at a 5 second integration time, and even explored the viability of analyzing mixtures as a test of multiplexed detection.

Is there anything you’ve used this week that you’d take back to your own work?

In my project, I’m using super resolution microscopy SRM to look at protein aggregates for Parkinson’s. Our goal is to find a marker for a specific protein, not just all proteins. Having done this course, I might think about comparing to a Raman tag or Raman reporter.

– Alexander Chappard

Winners all ’round

Seeing the students’ passion ingenuity in finding solutions from within the new tool set they’d been given was quite amazing. Their excitement at discovering the world of spectroscopy, and the possibilities it opened up for them took us right back to learning those principles and aligning that first spectrometer as students ourselves. It reminded us why we do what we do at Wasatch Photonics. It’s not just about solving problems and pushing the limits of new applications – it’s also about a sheer love for science and what it can achieve.

Industrial Placements: Firsthand experience

In addition to the Build Your Own Spectrometer Course, OPTIMA students participate in a variety of other integrated studies, including courses in entrepreneurship, ethics & regulatory processes, and technology commercialization. They also take part in a 3-month industrial placement during their 3rd year to gain inside perspective on life in industry, and to explore and share the many possible career paths that originate in science. These internships take them into research labs, production floors, healthcare administration & policy, finance, and even illustration and publishing.

At Wasatch Photonics, we were lucky enough to host Hazel Stewart in summer 2018 for her industrial placement, drawing on her experience in fluorescence spectroscopy for product characterization and applications testing (you may have seen her work on saffron quality).

“Some students come in knowing where they’d like to do their placement. Others don’t quite know what they want to do. I try to get to know each student to see where they might fit, and find a placement that’s uniquely suited to their interests and personality. It’s quite incredible how some come to pass – I’ve drawn on new and old connections, far and wide, in addition to our industry partners.”

— Kirsty Ross, Outreach Officer, CDT OPTIMA