At Wasatch Photonics, our volume phase holographic transmission grating technology is at the heart of everything we do. Here, we share the many advantages of VPH gratings over reflective ruled gratings, and how we make the most of each one! With benefits ranging from superior optical performance and design flexibility to robustness and consistency, VPH gratings are ideal for applications like laser pulse compression, spectroscopy, optical coherence tomography, and astronomy.

At Wasatch Photonics, our volume phase holographic transmission grating technology is at the heart of everything we do. Here, we share the many advantages of VPH gratings over reflective ruled gratings, and how we make the most of each one! With benefits ranging from superior optical performance and design flexibility to robustness and consistency, VPH gratings are ideal for applications like laser pulse compression, spectroscopy, optical coherence tomography, and astronomy.

Wavelengths: 300-2500 nm | Bandwidth: 5-800 nm | Frequency: 150-5000 lines/mm

Each Grating is an Original

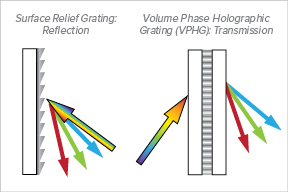

We produce our volume phase holographic (VPH) transmission gratings by imaging a periodic structure of high and low index of refraction regions or areas into dichromated gelatin sealed between two optical windows. The technique was originally commercially deployed by IBM in holographic barcode scanners, but has since been adapted for use in many optical instruments, as well as telecommunications. This process allows us to generate very high quality diffraction gratings in volumes of 1 to 1000 pieces or more. With no primary or original grating to wear out through replication, we can deliver consistent performance from one grating to the next over long periods of time without degradation from copying. As originals, we can also customize and optimize our gratings much more easily and cost-effectively for each application by adjusting groove density, bandwidth, polarization sensitivity, and other parameters – in multiple iterations!

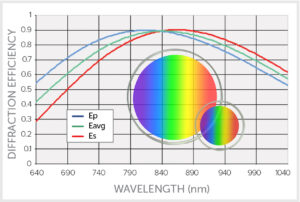

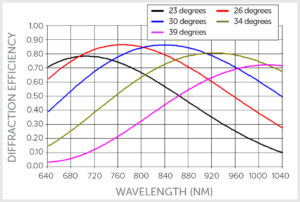

Beautiful Efficiency Curves

The transmissive, holographic nature of our VPH gratings allows them to operate at high peak diffraction efficiencies, ranging from >80% for a 200-300 nm bandwidth to >99% for a single wavelength for Bragg conditions. This is up to 40% greater than reflective surface relief gratings, which can have very jagged, asymmetric efficiency profiles that wreak havoc with system response. A VPH grating’s efficiency varies smoothly with wavelength, and can be modeled at the design stage for inclusion in system performance models, and then manufactured dependably based upon that design.

The transmissive, holographic nature of our VPH gratings allows them to operate at high peak diffraction efficiencies, ranging from >80% for a 200-300 nm bandwidth to >99% for a single wavelength for Bragg conditions. This is up to 40% greater than reflective surface relief gratings, which can have very jagged, asymmetric efficiency profiles that wreak havoc with system response. A VPH grating’s efficiency varies smoothly with wavelength, and can be modeled at the design stage for inclusion in system performance models, and then manufactured dependably based upon that design.

The encapsulated nature of our VPH gratings also allows the application of high‐performance, anti-reflection (AR) coatings on the surfaces of the element. These coatings offer further optimization of performance, and can be customized as needed for OEMs.

High Dispersion

VPH gratings can be reliably generated with higher line densities than ruled gratings, delivering high quality gratings with low ghosting and scatter at line densities ranging from 150 to near 5000 lines/mm, serving applications as diverse as broadband NIR hyperspectral imaging and high resolution atomic spectroscopy. The flexibility of our manufacturing process allows us to easily customize the line density and wavelength of operation for your needs.

Reduced Polarization Sensitivity

Surface relief reflection gratings typically offer much lower efficiency for p-polarization than s-polarization, often with very different efficiency response between the two states. This is particularly evident as the line frequency of the grating increases. VPH gratings are far less sensitive to polarization, with the added benefit that the polarization response is both smoothly varying and well understood. We offer several design solutions, including our patented Dickson and HD gratings, which allow us to minimize and/or optimize polarization response specifically for your application.

More Compact, Flexible Optical Designs

A transmission grating is a very simple way to make an optical design more compact, as transmission gratings can be designed to work in the Littrow configuration (Ɵd = Ɵi). In general, transmission gratings offer the optical engineer more geometry options, whether designing a pulse compression system or a spectrometer. The net result is that a system designed around a Wasatch Photonics VPH grating is likely to be smaller, lighter and less expensive than one designed around a conventional reflection grating, in addition to being easier to align.

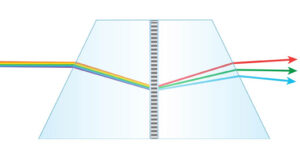

Grisms

A grating sandwiched between two prisms is called a grism. This compound optic separates light into its components while canceling out the beam deviations caused by each element. Grisms can be used to either create a straight pass dispersive optic or an optic with dispersion higher than is possible with a grating alone. They are convenient for use in imaging, astronomy, spectrally encoded confocal microscopy, and other applications. Learn more about grisms.

A grating sandwiched between two prisms is called a grism. This compound optic separates light into its components while canceling out the beam deviations caused by each element. Grisms can be used to either create a straight pass dispersive optic or an optic with dispersion higher than is possible with a grating alone. They are convenient for use in imaging, astronomy, spectrally encoded confocal microscopy, and other applications. Learn more about grisms.

Angle Tuning

VPH transmission gratings diffract light using stacked layers of sinusoidally varying index. This stack creates a resonant structure that can be tuned in center wavelength simply by varying the angle of incidence (AOI) by up to ~10°. This allows a single grating to be angle-tuned to study spectral features of interest in different ranges, a common technique in astronomy. In fact, several very large gratings on rotating stages may be used in a single large scale telescope to cover the visible through near infrared continuously.

VPH transmission gratings diffract light using stacked layers of sinusoidally varying index. This stack creates a resonant structure that can be tuned in center wavelength simply by varying the angle of incidence (AOI) by up to ~10°. This allows a single grating to be angle-tuned to study spectral features of interest in different ranges, a common technique in astronomy. In fact, several very large gratings on rotating stages may be used in a single large scale telescope to cover the visible through near infrared continuously.

No Ghosting, Low Scatter

Ruled gratings are prone to “ghosts”, a term used to describe light artefacts which appear in the dispersion plane due to periodic ruling errors. VPH gratings can be designed to eliminate ghosting. They also have 90% less stray light than ruled gratings, excellent spatial uniformity, and very low transmitted wavefront error. These factors are all important contributors to the excellent 1st order diffraction efficiency of VPH gratings.

Excellent Durability

The optically active portion of a VPH grating is sealed between 2 substrates, creating a very robust component that offers excellent thermal stability and environmental performance. Many of our gratings have been in service for 10+ years with no signs of degradation, while others have been deployed at near cryogenic temperatures. This allows our gratings to be used in a wide range of applications, from laser pulse compression, spectroscopy, and biomedical devices to astronomy.

Easy to Clean

Everyone knows never to touch a ruled, reflective grating, as they cannot be cleaned – every speck of dust or fingerprint must remain, as the scratching that would occur from “cleaning” would be worse than the contamination itself! In contrast, our encapsulated VPH gratings can be handled and cleaned like any other glass optical component, making them much more manufacturing-friendly and reducing cost at every stage, from build through long-term use.

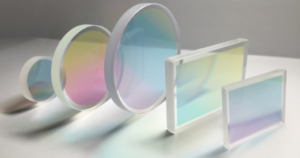

Size & Substrates – Big & Small

VPH gratings can be made much larger than one might expect – in fact, we routinely manufacture custom gratings up to 300 mm in size for astronomical spectrographs (larger sizes upon request). They can also be cut to as small as 8 mm across for volume OEM applications. Many different types of glass materials may be used for manufacture, the most common substrates being N-BK7 or equivalent, B270i, and fused silica (UV optional).

VPH gratings can be made much larger than one might expect – in fact, we routinely manufacture custom gratings up to 300 mm in size for astronomical spectrographs (larger sizes upon request). They can also be cut to as small as 8 mm across for volume OEM applications. Many different types of glass materials may be used for manufacture, the most common substrates being N-BK7 or equivalent, B270i, and fused silica (UV optional).

We stand behind the quality of our optics with advanced interferometric measurement capabilities for critical applications like laser pulse compression, optical coherence tomography, and astronomy. Our metrology lab sports a new state of the art Zygo Verifire™ capable of measuring up to 4” optics!

Conclusion

When the founders of Wasatch Photonics began writing volume phase gratings in dichromated gelatin over 40 years ago, it was because they knew VPH grating technology had the performance, flexibility, and ability to scale from prototype to volume for a wide range of applications. Since then, we’ve worked hard to offer the quality and consistency you should expect from an experienced volume gratings supplier. Contact us to discuss your unique needs today!

Learn more about our VPH Gratings for:

Contact us to discuss your grating application

Wavelengths: 300-2500 nm | Bandwidth: 5-800 nm | Frequency: 150-5000 lines/mm

Pulse Compression

Pulse Compression OCT

OCT Hyperspectral Imaging

Hyperspectral Imaging Astronomy

Astronomy Spectroscopy

Spectroscopy Grisms

Grisms